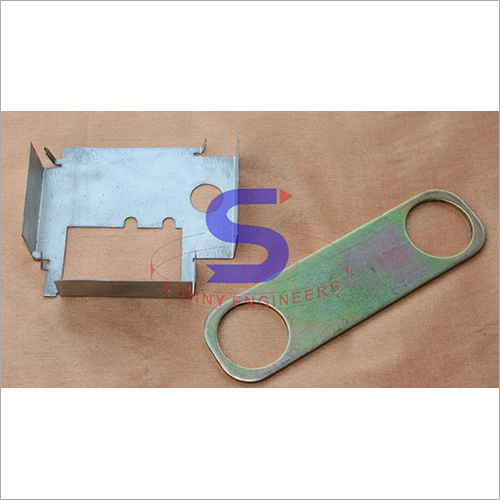

Precision Pressed Components

Price 5 INR/ Piece

Precision Pressed Components Specification

- Weight

- Varies by dimension

- Components

- Brackets, Clips, Covers

- Surface Finishing

- Smooth, Deburred

- Coating Type

- Anti-corrosion

- Shape

- Rectangular, Custom shapes

- Application

- Automotive, Electronics, Industrial machinery

- Hole Size

- As per design specification

- Mount Type

- Panel mount, Surface mount

- Dimension (L*W*H)

- Custom as per requirement

- Usage

- Mechanical assembly, Electrical enclosures

- Material

- Cold rolled steel, Stainless steel

- Tolerance

- Up to 0.05 mm

- Thickness

- 0.5 mm - 5 mm

- Capacity

- High volume production capability

- Surface Treatment

- Zinc plating, Powder coating

- Making Process

- Precision stamping

Precision Pressed Components Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 30 Days

About Precision Pressed Components

In the event that you are searching for the inventory of high evaluation Precision Pressed Components is highly appreciated in the market because of its high quality and durability. It is mostly utilized for the production applications. Our firm is considered as a part of the highest favored decisions for countless customers because of the subjective things that we convey. This Precision Pressed Components can be avail from us at cost-effective price rate without any delay.

Specification

Country of Origin | Made in India |

Usage/Application | Industrial |

Customizable to Your Specifications

Precision Pressed Components are tailored to meet unique OEM and ODM requirements. Whether you need specific dimensions, custom colors, or intricate shapes, our advanced CNC machining and stamping processes ensure your components match exact design specifications. With options for surface treatments and various mounting types, flexibility is at the core of our manufacturing approach.

Exceptional Durability and Finish

Built from premium cold rolled or stainless steel, these components excel in high-heat environments up to 200C and endure demanding mechanical usage. With anti-corrosion coatings and smooth, deburred surfaces, each part combines longevity with a professional finish that fits automotive, industrial, or electronic applications.

Quality Assured for Every Application

Every component produced meets internationally recognized quality standards, offering consistent performance and precise fit. Our advanced production facilities and diligent quality control deliver components with tight tolerances and enhanced resistance to wear, corrosion, and customization needs.

FAQs of Precision Pressed Components:

Q: How can these pressed components be customized for specific OEM or ODM needs?

A: We offer comprehensive customization, including dimensions, shapes, hole sizes, colors, and surface treatments. Our team works closely with clients to develop components that match their technical drawings and system requirements, supported by precise CNC machining and stamping.Q: What processes are used to ensure high precision and quality?

A: Precision stamping and advanced CNC machining are utilized to achieve tight tolerances up to 0.05 mm. Components undergo laser cutting and deburring to guarantee smooth edges, while rigorous quality checks confirm adherence to international standards.Q: When should I opt for enhanced rust or heat resistance in my components?

A: Selecting anti-corrosion coatings and heat-resistant materials is recommended for components used in harsh or temperature-intensive environments, such as automotive or industrial applications, to ensure prolonged durability and function.Q: Where are these components typically used?

A: They are widely implemented in automotive assemblies, electrical enclosures, industrial machinery, and various mechanical sub-systems, serving as brackets, covers, clips, and other critical hardware.Q: What packaging solutions are available for bulk or custom shipments?

A: We provide bulk packing for large volume orders and offer custom packaging tailored to protect components during transit, based on the clients preferences and destination requirements.Q: How does the surface treatment enhance the benefit of these components?

A: Surface treatments such as zinc plating and powder coating increase resistance to rust and corrosion, ensuring components maintain their integrity and appearance even in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Components Category

Precision Sheet Metal Components

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Mount Type : Panel Mounted, Wall Mounted, Floor Mounted

Dimension (L*W*H) : Custom as per requirement

Hole Size : Customized as per drawing

Usage : Electrical, Electronics, Automotive and Machinery

Tubular Pressed Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Mount Type : Bolton, Weldon

Dimension (L*W*H) : Customizable as per requirements

Hole Size : 3 mm to 25 mm

Usage : Mechanical and Automotive Assemblies

Precision Pressed Parts

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Mount Type : Screw Mount

Dimension (L*W*H) : 45 mm x 30 mm x 5 mm

Hole Size : 2.5 mm

Usage : Industrial Assembly and Machinery

Sheet Metal Stampings

Price 5 INR / Piece

Minimum Order Quantity : 500 Pieces

Mount Type : Panel Mount, Surface Mount, Custom Mount

Dimension (L*W*H) : Custom as per requirement

Hole Size : As per specification

Usage : Industrial, Electrical, Automotive, Construction

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS